Automated test and measurement software is based on efficiency, safety, and reliability considerations, and has become an integral part of modern test and production processes or missing components. The automated test systems we develop are widely used in scientific research and product development. From R&D From validation to end-of-line testing, we offer complete solutions.

Our automated data acquisition and processing systems enable rapid acquisition of complex measurement results to help R&D teams optimize their tests.

process. During the production process, these systems can effectively improve product quality and production efficiency.

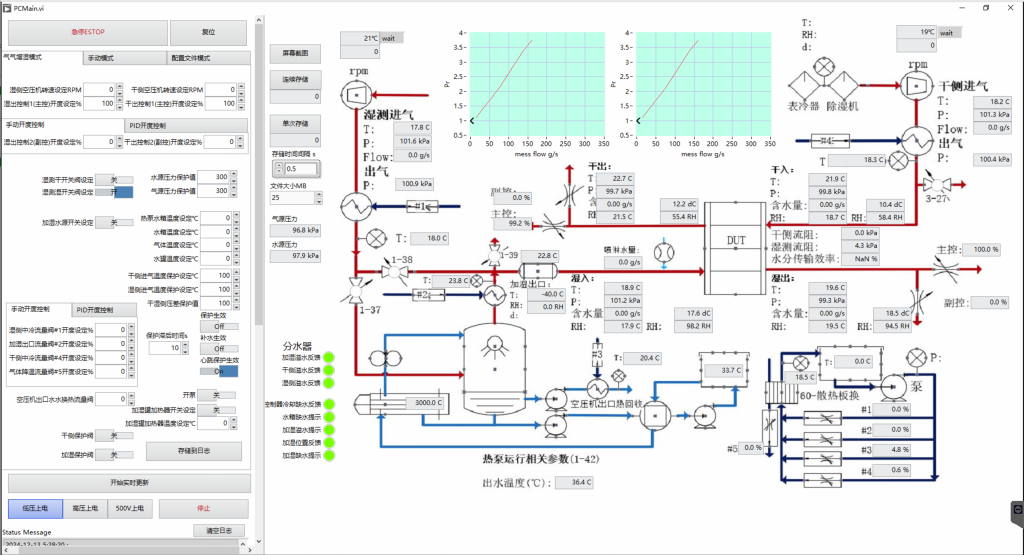

Bench test system software

Excellent power system bench test equipment not only requires high-quality test hardware, but also excellent test software is more critical for complex test scenarios. Our software is perfectly integrated into powertrains, auxiliary systems, loading systems and test systems. It can simulate various working conditions and provide precise control and test data support.

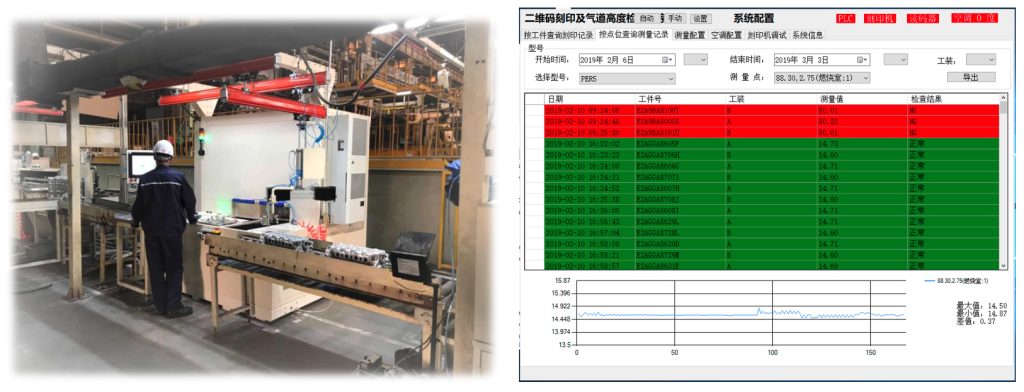

Production process and EOL automation software development

Production process and product terminal quality inspection intelligent and automation software development

We help manufacturing companies cope with the pressure to reduce costs and increase efficiency, solve production bottlenecks caused by traditional manual testing and basic systems, and avoid costly product failures. Measurement and analysis performed by evaluation software can reliably identify production errors in end-of-line testing, providing key elements to ensure and improve manufacturing quality and ensure that product quality meets high standards.

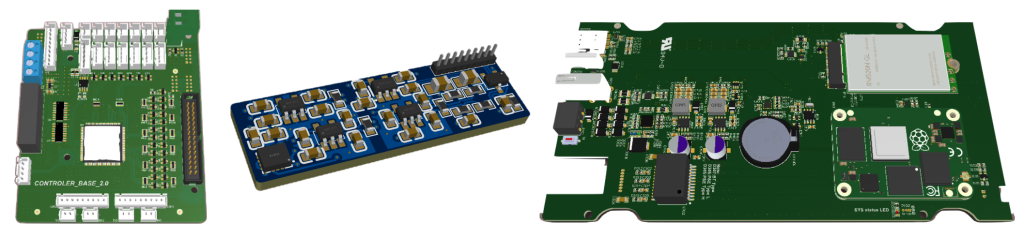

Mechatronics hardware design services

For specific usage needs, standard hardware in the market is often difficult to meet the needs, and the differences in hardware and software interfaces from various manufacturers bring integration barriers. We provide customized access hardware-to-software design and development services. The final step of complete mechatronics. It’s not just a system jigsaw puzzle.

Internet of Things data collection information management system

IoT data collection

We provide advanced IoT data collection information management systems to achieve full-link data management from the device end to the cloud. The system has powerful data collection, storage, and analysis capabilities, supporting multiple industrial protocols and communication methods to ensure real-time, accurate, and secure data transmission and processing. Through the visual management interface, enterprises can intuitively grasp the equipment operation status and production data, providing strong support for decision-making.

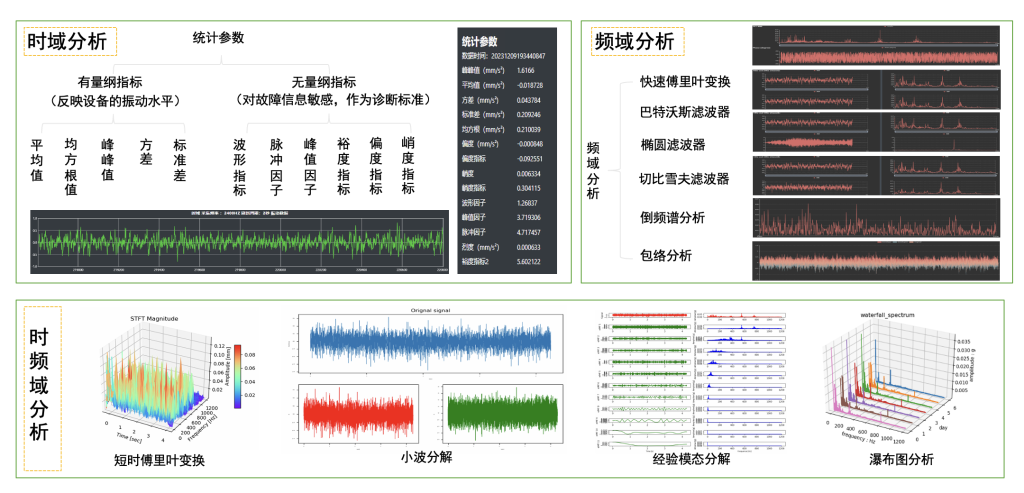

Device health data analysis

Through professional data analysis technology, we conduct in-depth monitoring and prediction of equipment operation status, helping enterprises achieve predictive maintenance and improve equipment utilization and operational efficiency. Based on traditional architecture, combined with modern AI models and data processing methods, it maximizes data utilization.

Intelligence – Intelligence from end to end to intelligent, fully stimulating the value of digital productivity. Intelligence is the core of Industry 4.0, and our equipment intelligent operation and maintenance platform takes intelligence as the core advantage, intelligence starts from the edge, and supports flexible configuration to achieve all-round intelligent management.

Flexible – Flexible scenarios and support customization of various sensors, making equipment operation and maintenance more convenient. In order to meet the adaptation needs of different industrial scenarios, different industries, and different types of scenarios, our equipment intelligent operation and maintenance platform gives customers a high degree of autonomy and can quickly add various sensor devices.

Diversified – Microservices and multiple interfaces provide the foundation for multiple business integrations. In order to meet the construction needs of future smart factories, we adopt a cluster service architecture, which separates the front and back, and has strong up-to-down compatibility and expansion capabilities.